UV-C LED Technology

UVC-based disinfection, often called, Ultraviolet germicidal irradiation (UVGI), is the use of ultraviolet (UV) light to kill or inactivate viral, bacterial, and fungal species. When UV-C light is incident upon the target, the incident photons are absorbed by DNA or RNA, causing inactivation of the DNA or RNA double helix strands through the formation of molecular lesions. When enough of these lesions are created, the replication process is disrupted, and the cell cannot replicate. Absorption by proteins can lead to the breakdown of the organism’s cell walls causing the cell to die. For most commercial applications, replication prevention is sufficient. The UV doses required to prevent replication are much lower than required to kill, making the cost of UV treatment to prevent infection commercially viable

UVC LED Disinfection

UV-C based LEDs are a relatively new technology. Examples of wavelengths currently commercially available include 255nm, 265nm, 275nm, and 222nm. Cependant, Technologie LED UV-C se développe rapidement, et au fil du temps, de nouvelles longueurs d'onde seront développées, les coûts diminueront et l’efficacité augmentera, comme cela s’est déjà produit dans le rouge., infrarouge, bleu, et gammes de LED de longueur d'onde UV-A.

A wavelength of 265nm is considered the optimum as it’s the peak of the DNA absorption curve. Cependant, disinfection and sterilization occur over a range of wavelengths. UV-C LEDs can be manufactured to target very specific and narrow wavelengths. This allows solutions to be tailored to the particular application need.

LED UVC vs. Technologies traditionnelles

Many applications use Mercury based UV lamps for UV disinfection applications but this technology has a number of disadvantages versus LED technology. Il existe une réglementation accrue concernant l'utilisation du mercure et son impact environnemental, ce qui entraîne une augmentation des coûts d'élimination et des propositions d'interdiction dans certains pays.. Ces systèmes nécessitent également l'utilisation de chlore pour permettre la désinfection et sont généralement beaucoup plus grands que les systèmes à LED..

Modules LED UVC Application:

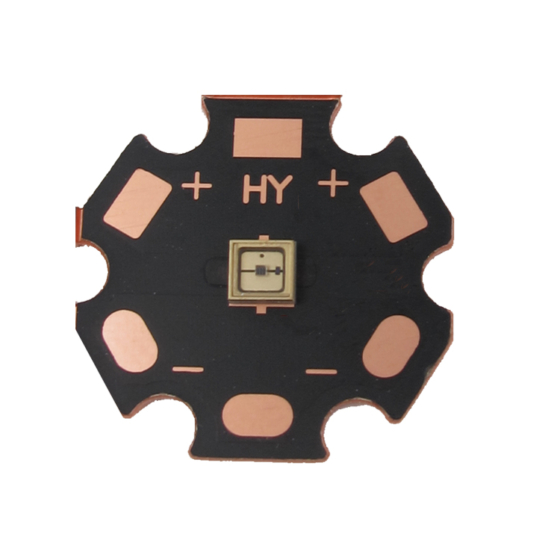

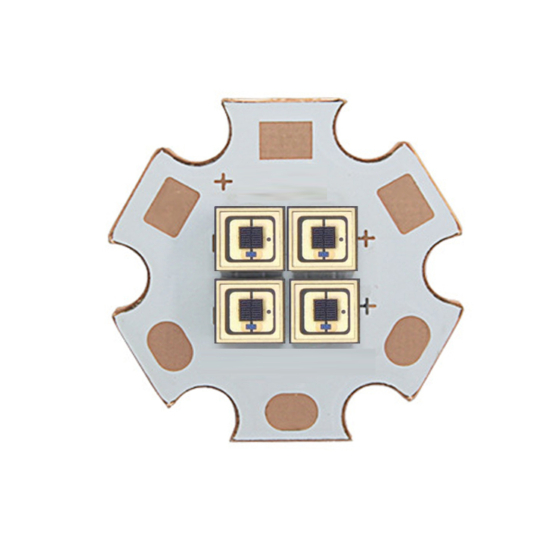

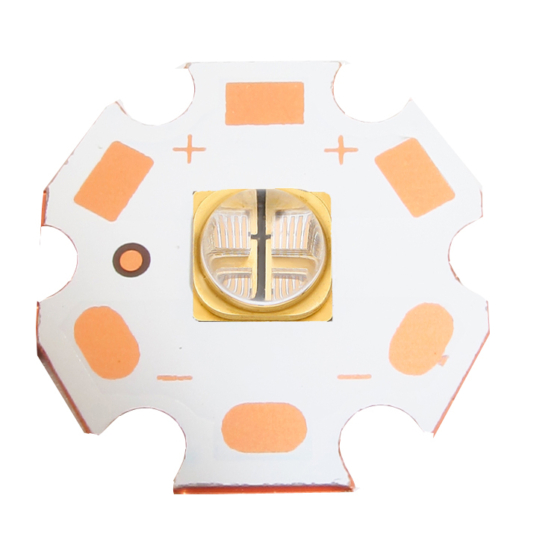

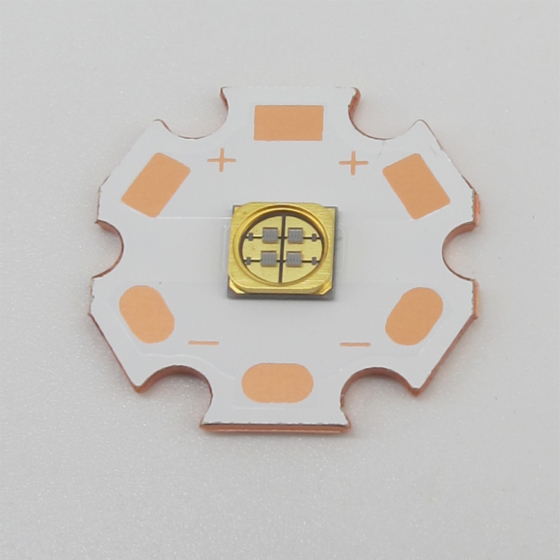

| Modèle de produit |

Tension (V) |

Longueur d'onde maximale (nm) |

Puissance optique (mW) |

Intensité Rdiant uw/cm²(1cm) |

Actuel (mA) |

Spectre moitié (nm) |

Angle |

| HYE35P20F250AG-P1 | 5.5-6.0 | 250-260 | 25-30 | 2718 | 150 | 11 | 120 |

| HYE35P20D250AG-P1 | 5.5-6.0 | 250-260 | 30-35 | 2278 | 150 | 11 | 120 |

| HYE35P20F260AG-P1 | 5.0-5.5 | 260-270 | 30-35 | 3244 | 150 | 11 | 120 |

| HYE35P20F270AG-P1 | 5.0-5.5 | 270-280 | 30-35 | 4560 | 150 | 11 | 120 |

| HYE35P22D270AG-P1 | 5.0-5.5 | 270-280 | 80-90 | 6144 | 250 | 11 | 120 |

| HYE35P30F250AG-P1 | 5.5-6.0 | 250-260 | 50-60 | 5571 | 350 | 11 | 120 |

| HYE35P30F260AG-P1 | 5.0-5.5 | 260-270 | 50-60 | 5546 | 350 | 11 | 120 |

| HYE35P30F270AG-P1 | 5.0-5.5 | 270-280 | 50-60 | 5571 | 350 | 11 | 120 |

| HYF38P20F250AG-D1 | 5.5-6.0 | 250-260 | 25-30 | 9177 | 150 | 11 | 120 |

| HYF38P20D250AG-D1 | 5.5-6.0 | 250-260 | 30-35 | 8727 | 150 | 11 | 120 |

| HYF38P20F260AG-D1 | 5.0-5.5 | 260-270 | 30-35 | 10301 | 150 | 11 | 120 |

| HYF38P20F270AG-D1 | 5.0-5.5 | 270-280 | 30-35 | 11814 | 150 | 11 | 120 |

| HYF38P22F270AG-D1 | 5.0-5.5 | 270-280 | 80-90 | 23550 | 250 | 11 | 120 |

| HYF38P30F250AG-D1 | 5.5-6.0 | 250-260 | 50-60 | 26744 | 350 | 11 | 120 |

| HYF38P30F260AG-D1 | 5.0-5.5 | 260-270 | 50-60 | 28038 | 350 | 11 | 120 |

| HYF38P20F250AG-S1 | 5.5-6.0 | 250-260 | 25-30 | 10515 | 150 | 11 | 30 |

| HYF38P20D250AG-S1 | 5.5-6.0 | 250-260 | 30-35 | 15972 | 150 | 11 | 30 |

| HYF38P20F260AG-S1 | 5.0-5.5 | 260-270 | 30-35 | 11874 | 150 | 11 | 30 |

| HYF38P20F270AG-S1 | 5.0-5.5 | 270-280 | 30-35 | 21872 | 150 | 11 | 30 |

| HYF38P22D270AG-S1 | 5.0-5.5 | 270-280 | 80-90 | 43160 | 250 | 11 | 30 |

| HYF38P30F250AG-S1 | 5.5-6.0 | 250-260 | 50-60 | 35123 | 350 | 11 | 30 |

| HYF38P30F260AG-S1 | 5.0-5.5 | 260-270 | 50-60 | 35007 | 350 | 11 | 30 |

| HYF38P30F270AG-S1 | 5.0-5.5 | 270-280 | 50-60 | 35407 | 350 | 11 | 30 |

Astuce de chaleur: The company is willing to personalize your customized products.

Plus la dose d'irradiation est élevée, plus l'efficacité de la désinfection est élevée.

The higher the UVB light power, plus le temps nécessaire pour tuer les bactéries et les virus est court, et vice versa, plus la puissance lumineuse est faible,Plus la stérilisation est longue.

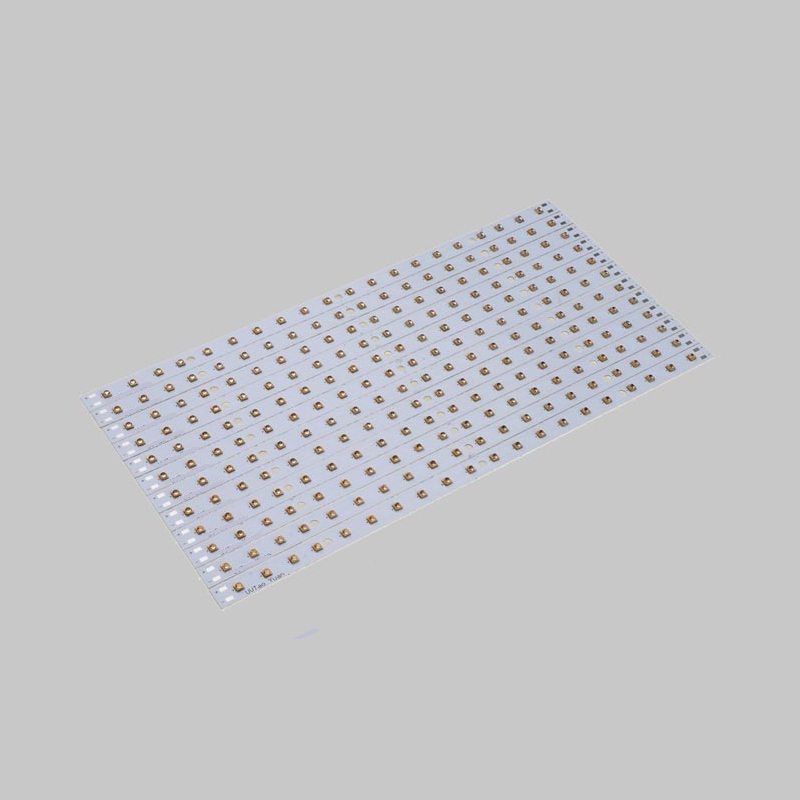

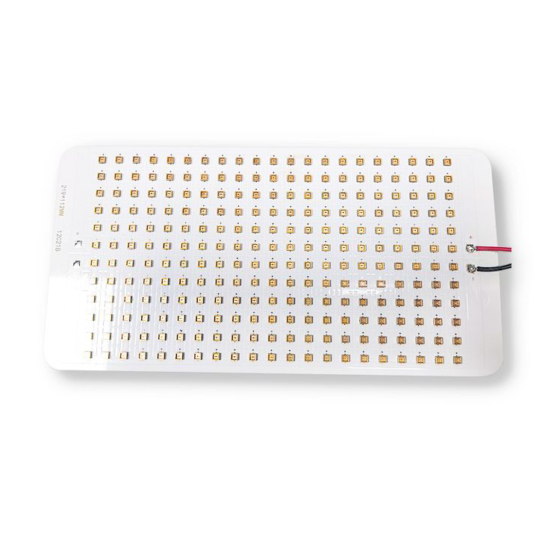

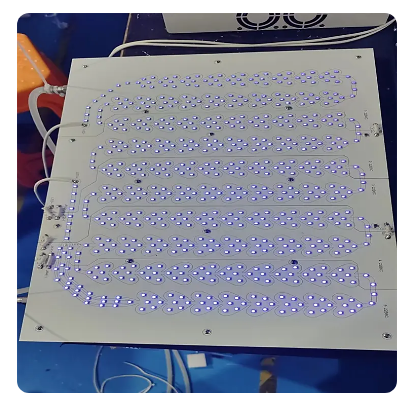

Module de carte Solar Somilateur LED 200-1750 nm

Module de carte Solar Somilateur LED 200-1750 nm