High-power UVC LED Modules

UV-Cbased LEDs are a relatively new technology. Exemplos de comprimentos de onda atualmente disponíveis comercialmente incluem 222nm, 235nm, 255nm, 254nm, 265nm 275nm, and 270nm No entanto, UV-C LED technology está se desenvolvendo rapidamente, e com o tempo novos comprimentos de onda serão desenvolvidos, Os custos reduzirão e a eficiência aumentará como já aconteceu no vermelho, infravermelho, azul, and UV-C wavelength LED ranges.

LEDs UVC vs.. Tecnologias tradicionais

Muitas aplicações usam lâmpadas UV baseadas em mercúrio para Iluminação UVC Aplicações, mas essa tecnologia tem várias desvantagens versus a tecnologia LED. Há um aumento da regulamentação em torno do uso de mercúrio e seu impacto ambiental, resultando em aumento de custos de descarte e propostas propostas em alguns países. Esses sistemas também exigem o uso de cloro para permitir a desinfecção e são tipicamente muito maiores que os sistemas baseados em LED.

UVC LED Modules Aplicativo:

| Modelo do produto |

Tensão (V) |

Comprimento de onda de pico (nm) |

Potência óptica (MW) |

RdiantIntensidade uw/cm²(1cm) |

Atual (MA) |

Spectrum metade (nm) |

Ângulo |

| HYE35P20F250AG-P1 | 5.5-6.0 | 250-260 | 25-30 | 2718 | 150 | 11 | 120 |

| HYE35P20D250AG-P1 | 5.5-6.0 | 250-260 | 30-35 | 2278 | 150 | 11 | 120 |

| HYE35P20F260AG-P1 | 5.0-5.5 | 260-270 | 30-35 | 3244 | 150 | 11 | 120 |

| HYE35P20F270AG-P1 | 5.0-5.5 | 270-280 | 30-35 | 4560 | 150 | 11 | 120 |

| HYE35P22D270AG-P1 | 5.0-5.5 | 270-280 | 80-90 | 6144 | 250 | 11 | 120 |

| HYE35P30F250AG-P1 | 5.5-6.0 | 250-260 | 50-60 | 5571 | 350 | 11 | 120 |

| HYE35P30F260AG-P1 | 5.0-5.5 | 260-270 | 50-60 | 5546 | 350 | 11 | 120 |

| HYE35P30F270AG-P1 | 5.0-5.5 | 270-280 | 50-60 | 5571 | 350 | 11 | 120 |

| HYF38P20F250AG-X1 | 5.5-6.0 | 250-260 | 25-30 | 9177 | 150 | 11 | 60 |

| HYF38P20D250AG-X1 | 5.5-6.0 | 250-260 | 30-35 | 8727 | 150 | 11 | 60 |

| HYF38P20F260AG-X1 | 5.0-5.5 | 260-270 | 30-35 | 10301 | 150 | 11 | 60 |

| HYF38P20F270AG-X1 | 5.0-5.5 | 270-280 | 30-35 | 11814 | 150 | 11 | 60 |

| HYF38P22F270AG-X1 | 5.0-5.5 | 270-280 | 80-90 | 23550 | 250 | 11 | 60 |

| HYF38P30F250AG-X1 | 5.5-6.0 | 250-260 | 50-60 | 26744 | 350 | 11 | 60 |

| HYF38P30F260AG-X1 | 5.0-5.5 | 260-270 | 50-60 | 28038 | 350 | 11 | 60 |

| HYF38P20F250AG-S1 | 5.5-6.0 | 250-260 | 25-30 | 10515 | 150 | 11 | 30 |

| HYF38P20D250AG-S1 | 5.5-6.0 | 250-260 | 30-35 | 15972 | 150 | 11 | 30 |

| HYF38P20F260AG-S1 | 5.0-5.5 | 260-270 | 30-35 | 11874 | 150 | 11 | 30 |

| HYF38P20F270AG-S1 | 5.0-5.5 | 270-280 | 30-35 | 21872 | 150 | 11 | 30 |

| HYF38P22D270AG-S1 | 5.0-5.5 | 270-280 | 80-90 | 43160 | 250 | 11 | 30 |

| HYF38P30F250AG-S1 | 5.5-6.0 | 250-260 | 50-60 | 35123 | 350 | 11 | 30 |

| HYF38P30F260AG-S1 | 5.0-5.5 | 260-270 | 50-60 | 35007 | 350 | 11 | 30 |

| HYF38P30F270AG-S1 | 5.0-5.5 | 270-280 | 50-60 | 35407 | 350 | 11 | 30 |

Dica de calor:A empresa está disposto para personalizar seu personalizado produtos.

Quanto maior a dose de irradiação, quanto maior a eficiência da desinfecção.

The higher the UVC light power, quanto menor o tempo necessário para matar bactérias e vírus, e vice-versa, quanto menor a potência da luz,Quanto mais tempo leva para esterilizar.

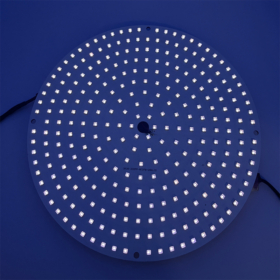

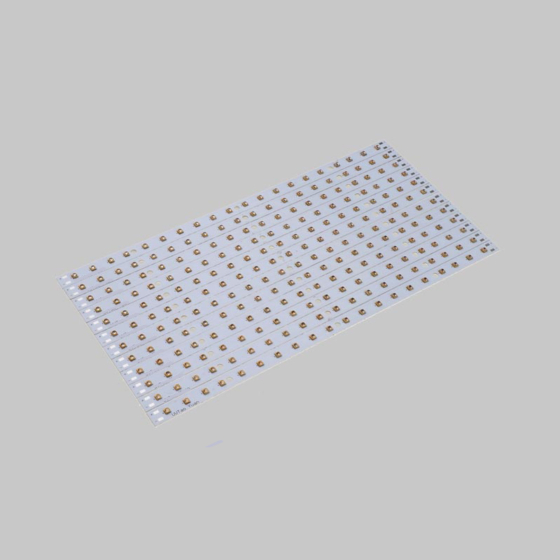

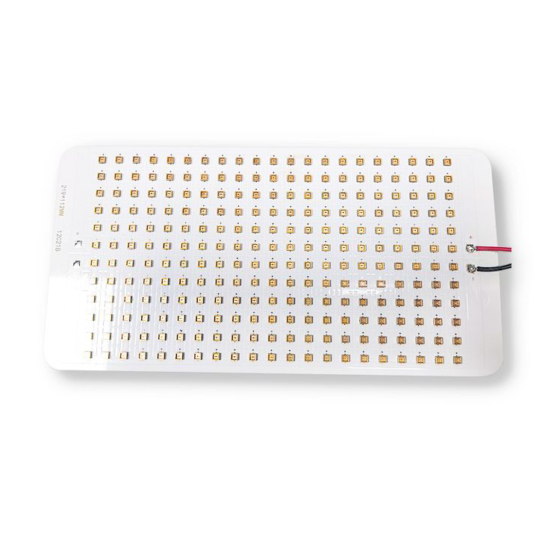

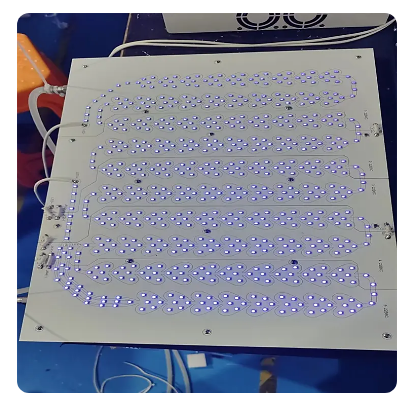

Simulador solar LED Módulo de placa PCBA 200-1750NM

Simulador solar LED Módulo de placa PCBA 200-1750NM