UVA LED Light Sources for Photochemical Processes

Specific UV light wavelength-intensity combinations create molecular interactions that result in the synthesis or separation of chemical compounds. From anti-cancer (Hydroxycamptothecin) or anti-malaria (artemisinin) drugs to powerful precursors (carbon tetrachloride), photochemistry has been the ideal mechanism for many chemical compound production systems in pharmaceutical, agricultural, cosmetic, petrochemical, plastics, dyes, and toxic waste disposal applications.

Photochemistry is revolutionizing the industrial chemistry landscape, however, it has long been tied to the limitations of UV mercury lamps. UV LED lamps are the perfect substitute to mercury and solve common shortcomings of the currently used light source.

Narrow Wavelength Light

With a single (narrow band) wavelength light, UV LED lamps ensure better yields by reducing undesirable products of secondary reactions and reducing raw material production cost.

Longer Lamp Life & Fewer Replacements

Phoseon’s lamp life tests have surpassed 60,000 hours of LED lamp lifetime, which equates to thirty years of LED on-time for a typical business.

Saves Power Costs

With optimizations, such as simplicity of the power supplies, Phoseon LED is able to save costs for customers.

Mercury-free

Mercury-free allows for no secondary containment and eliminates the risk of having to clean tanks and production lines in case of lamp breakage.

Consistent Performance Over Life

LEDs give the same results on day 1 through day until end of life. Hg lamps degrade through solarization and mercury condensation from day 1 of operation.

Lower Skin Temperature

Less heat added to reaction, less need for secondary containment.

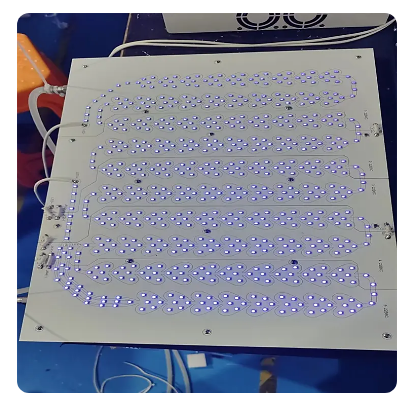

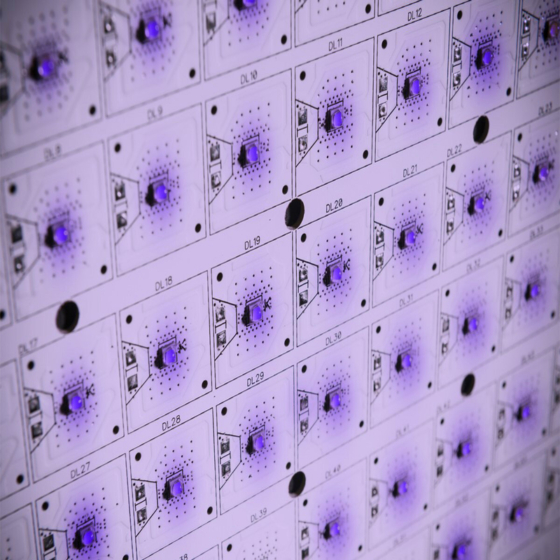

Heyi’s patented Semiconductor Light Matrix™ (HY)™ technology encompasses LED arrays, optics, thermal and electrical management to ensure optimal performance. Reliability Engineering is at our core. With over 15 patents worldwide, Phoseon has earned the reputation for innovation, quality and reliability.

We are ready to revolutionize the industrial chemistry landscape with the world’s first and best UV LED system. In addition, Phoseon’s customer support with experts in the field have driven our clients yield up 2-3x.

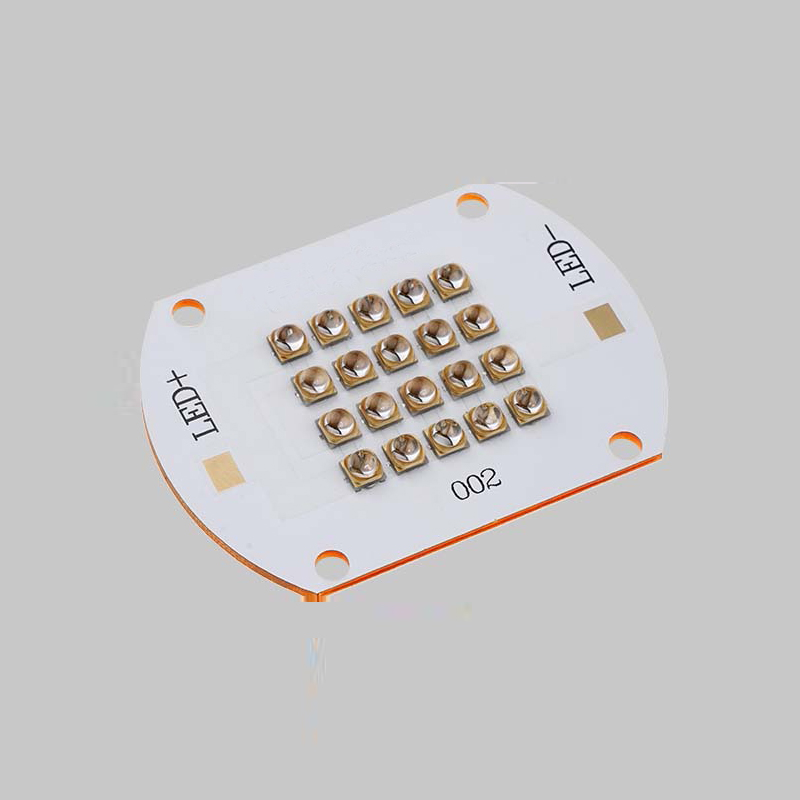

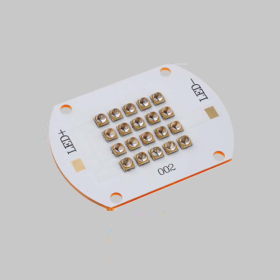

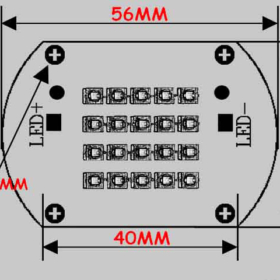

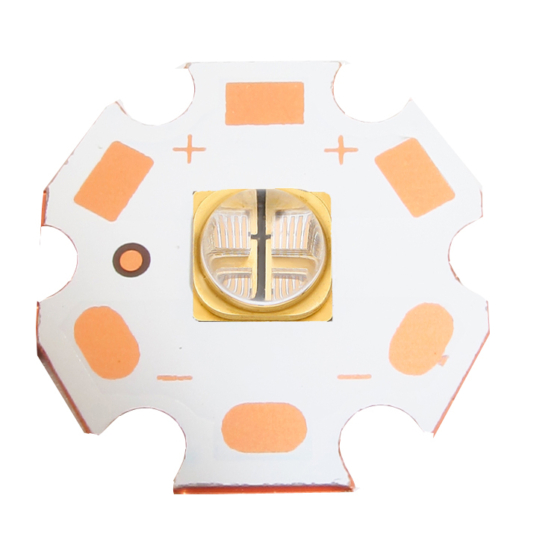

High-power UVA LED Modules

UV-A based LEDs are a relatively new technology. Examples of wavelengths currently commercially available include 365nm, 375nm, 385nm, 395m, 400nm 415nm,420m, 425nm 430nm, and 435nm However, UV-A LED technology is rapidly developing, and over time new wavelengths will be developed, costs will reduce and efficiencies will increase as has already happened within the red, infrared, blue, and UV-A wavelength LED ranges.

UVC LEDs vs. Traditional Technologies

Many applications use Mercury based UV lamps for UVC LIGHTING applications but this technology has a number of disadvantages versus LED technology. There is increased regulation around mercury usage and its environmental impact resulting in increased disposal costs and proposed bans in some countries. These systems also require the use of chlorine to enable disinfection and are typically much larger than LED-based systems.

UVA LED Modules Application:

We have designed solutions for:

Thermal Simulation & Design

Proper thermal management can be a crucial factor in system design that can be challenging with UVA LEDs in particular. Heyis offers customized thermal design and simulation services for your unique system.

Photocatalysis is a process that uses light to activate a catalyst, which then accelerates a chemical reaction without being consumed in the process. UV lighting is commonly used in photocatalysis to activate photocatalysts such as titanium dioxide (TiO₂). This technology is applied in various fields, including environmental purification, water treatment, air purification, and self-cleaning surfaces. UV light's ability to initiate these reactions efficiently makes it a crucial component in photocatalytic applications.

In collaboration with HEYI, the leading UV LED manufacturer, we produce high-quality UVA LED modules in Germany that offer powerful and efficient solutions for photocatalysis. These modules combine our 16 years of LED lighting experience with HEYI's expertise in UV LED manufacturing, ensuring exceptional radiant power, energy efficiency, and longevity. Our LED modules can be tailored to meet the specific needs of various industries, including luminaire manufacturers and medical technology companies. This collaboration ensures that our UVA LED modules provide the necessary precision and reliability required for effective photocatalytic processes, making them a top choice for applications in environmental and industrial purification.

SMD Packages

| Order Code |

Peak Wavelength |

Optical Power |

Voltage |

Rdiant Intensity |

IF(mA) |

Viewing |

Spectrum Half

width (nm) |

| nm/CIE |

IV(mW) |

IV(mW) |

VF(V) |

VF(V) |

(mW/sr) |

Angle(º) |

| min. |

max. |

min. |

max. |

| HYB35G45N365AG-D1 |

365-370 |

2200 |

2600 |

3.4 |

3.8 |

1692 |

1000 |

120 |

9 |

| HYB35G45N380AG-D1 |

380-390 |

2200 |

2600 |

3.0 |

3.4 |

1707 |

1000 |

120 |

10 |

| HYB35G45N400AG-D1 |

395-405 |

2000 |

2400 |

3.0 |

3.4 |

1533 |

1000 |

120 |

17 |

| HYB35E45N365AG-D1 |

365-370 |

3000 |

3500 |

3.6 |

4.0 |

2713 |

1500 |

120 |

9 |

| HYB35E43N380AG-D1 |

380-390 |

3000 |

3500 |

3.6 |

4.0 |

2208 |

1500 |

120 |

10 |

| HYB35E43N395AG-D1 |

395-400 |

3000 |

3500 |

3.6 |

4.0 |

2448 |

1500 |

120 |

17 |

| HYF38X43B365AG-D1 |

365-370 |

2500 |

3000 |

3.4 |

3.8 |

1923 |

1000 |

120 |

9 |

| HYF38X43B380AG-D1 |

380-390 |

2500 |

3000 |

3.0 |

3.4 |

1890 |

1000 |

120 |

10 |

| HYF38X43B400AG-D1 |

395-405 |

2000 |

2500 |

3.0 |

3.4 |

1538 |

1000 |

120 |

17 |

| HYB35G45N365AG-S1 |

365-370 |

2200 |

2600 |

3.4 |

3.8 |

3660 |

1000 |

30 |

9 |

| HYB35G45N380AG-S1 |

380-390 |

2200 |

2600 |

3.0 |

3.4 |

3681 |

1000 |

30 |

10 |

| HYB35G45N400AG-S1 |

400-405 |

2000 |

2400 |

3.0 |

3.4 |

3231 |

1000 |

30 |

17 |

| HYB35E45N365AG-S1 |

365-370 |

3000 |

3500 |

3.6 |

4.0 |

4712 |

1500 |

30 |

9 |

| HYB35E43N380AG-S1 |

380-390 |

3000 |

3500 |

3.6 |

4.0 |

4595 |

1500 |

30 |

10 |

| HYB35E43N395AG-S1 |

395-400 |

3000 |

3500 |

3.6 |

4.0 |

4817 |

1500 |

30 |

17 |

| HYF38X43B365AG-S1 |

365-370 |

2500 |

3000 |

3.4 |

3.8 |

4166 |

1000 |

30 |

9 |

| HYF38X43B380AG-S1 |

380-390 |

2500 |

3000 |

3.0 |

3.4 |

4203 |

1000 |

30 |

10 |

| HYF38X43B400AG-S1 |

400-405 |

2000 |

2500 |

3.0 |

3.4 |

3347 |

1000 |

30 |

17 |

Warmth Hint: The company is willing to personalize your customized products.

Heyis’ Programmable UVA LED Modules Pre-budgetary Quote Questionnaire

Q: When will you arrange the production?

A: We usually arrange the production immediately after receiving your payment if we have the item in stock. Otherwise, please confirm with us for lead time.

Q: What is your accepted payment type?

A: Wire transfer, Paypal and Western Union, and Alibaba Trade Assurance.We only accept Paypal and Western Union, and Alibaba Trade Assurance for payment amounts below USD400.

Q: What logistic forwarder do you usually work with?

A: We work with DHL, TNT, UPS, FEDEX and other logistric forwarders. Assigned your own forwarder for shipment is available.

Q:Is there any minimum order quantity (MOQ) requirement for the PCB Assembly order?

A: Generally, there is no minimum order quantity (MOQ) requirement for the pcb assembly order.

![]()

![]()

![]()

![]()

![]()

![]()

LED Solar simulator PCBA board module 200-1750nm

LED Solar simulator PCBA board module 200-1750nm