High-power UVC LED Modules

UV-Cbased LEDs are a relatively new technology. Examples of wavelengths currently commercially available include 222nm, 235nm, 255nm, 254nm, 265nm 275nm, and 270nm However, UV-C LED technology is rapidly developing, and over time new wavelengths will be developed, costs will reduce and efficiencies will increase as has already happened within the red, infrared, blue, and UV-C wavelength LED ranges.

UVC LEDs vs. Traditional Technologies

Many applications use Mercury based UV lamps for UVC LIGHTING applications but this technology has a number of disadvantages versus LED technology. There is increased regulation around mercury usage and its environmental impact resulting in increased disposal costs and proposed bans in some countries. These systems also require the use of chlorine to enable disinfection and are typically much larger than LED-based systems.

Why UV LEDs

With an increase in the type of ultraviolet (UV) light applications, the specific requirements for various industries are growing and there is a greater emphasis on higher light output, better thermal management, greater flexibility, and more adaptability. Companies require sophisticated, customized solutions to revitalize their business and industries such as horticulture, curing, and disinfection are making significant changes as they see a growth in research and development in UV technologies. While ultraviolet light has been used extensively for more than 40 years, ultraviolet light-emitting diodes are a promising entry offering a more sustainable solution than the incumbent lamp technologies. UV LEDs have risen to answer the current technological limitations with mercury lamp sources and hold the key to growth in industries worldwide. With a flexible form factor and an inherent ability for intensity and spectral control, UV LEDs can be integrated into various systems across several different applications.

UVC LED Modules Application:

Sterilization .Water decontamination.water and air purification.surface disinfection of consumer appliances..Medical application .Sensing of gases, germs, DNA

for mineral/gem detection.Medical devices .Blood Gas Measurements .Nitrogen Urea Measurements .UV-curing Applications

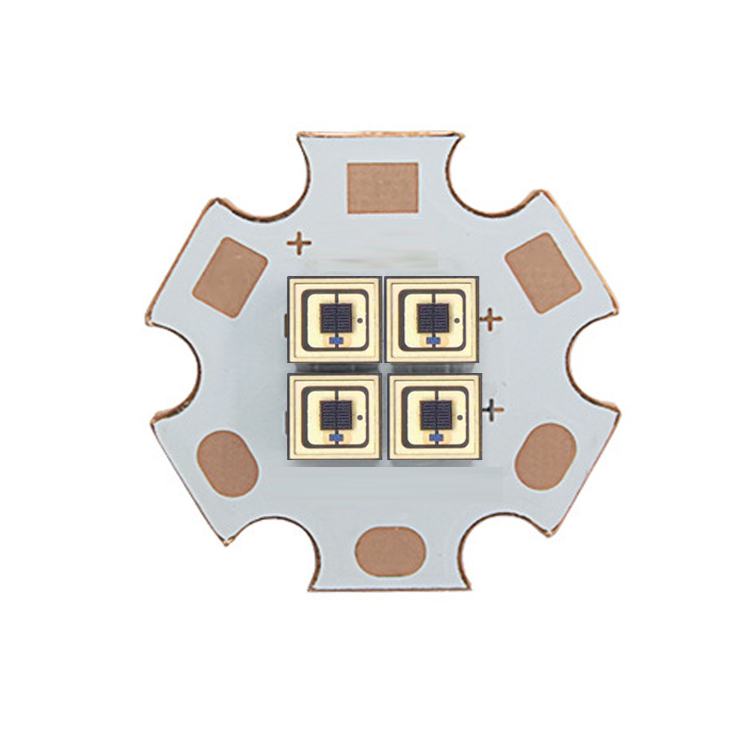

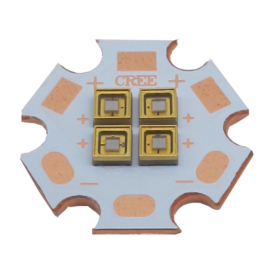

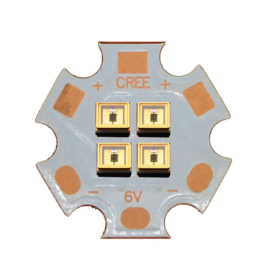

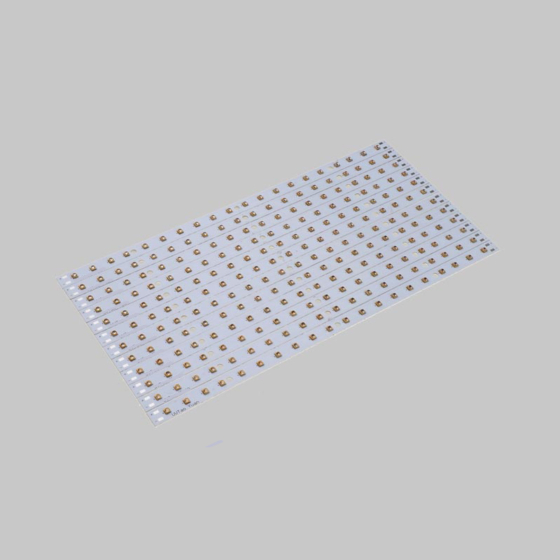

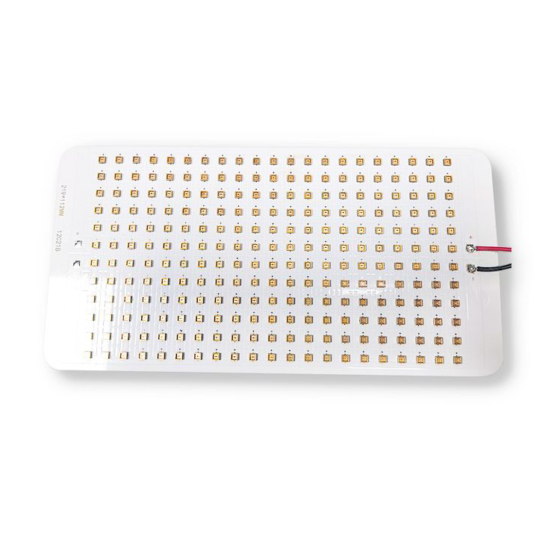

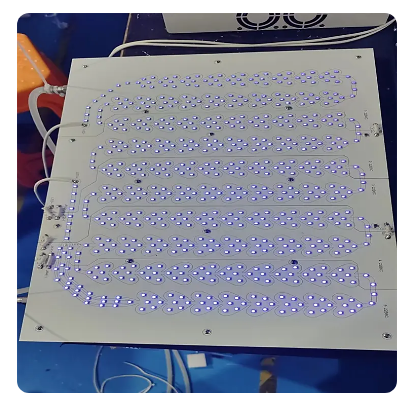

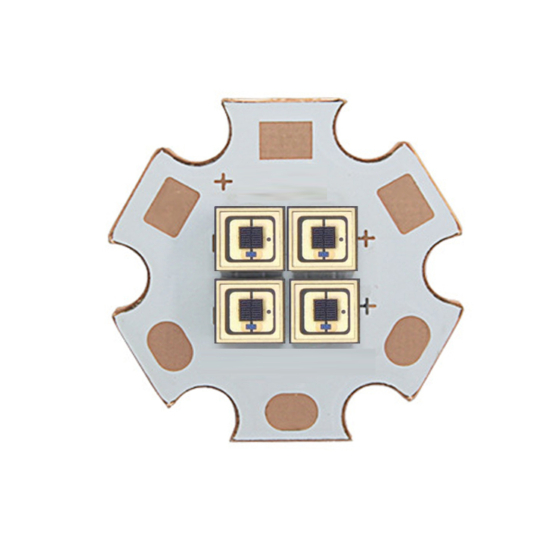

COB Modules for Easy Testing and Integration:

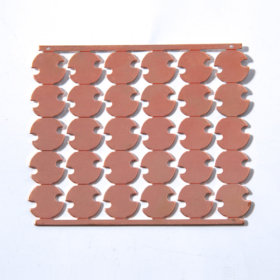

Chip on Board (COB) solutions give you more power in a flexible design. With chips bonded directly on a MCPCB in close configurations for increased efficiency, COB UVC LEDs have the lowest thermal resistance for the best reliability on the market. Heyis light bars and arrays are suitable for both retrofit and new designs.

UVC LED Packaging & Assembly

HEYIS supports both small-and large-scale manufacturing needs for UVC LED packaging and assembly with rapid turn around times. Leveraging years of experience in high power UVC LED manufacturing, we develop and utilize high-performance components, recipes, and processes to ensure your UVC LEDs are manufactured with the highest quality and precision.

COB Modules-Maximum optical output and ease of integration

→ With capability in optical simulation, circuit design, and bonding, Heyis can help optimize custom COB arrays to your specifications.

→ Heyis offers custom arrays and lightbars to ensure you see success in your UV solution for both prototyping and mass production purposes.

Heyis provides professional PCB circuit design services.

When clients need to design a new circuit or modify an existing one

We follow the following process:

Engineers will have discussions with clients to identify their product requirements and specification requirements.

Components Selection

We select the most suitable components based on the customer’s requirements, such as LEDs, protection devices, thermistors, resistors, capacitors, inductors, etc.

At the same time, we also consider factors such as component availability, cost, and reliability.

Circuit Design

Engineers design circuits based on customer requirements and selected components

Includes drawing circuit diagrams and determining circuit dimensions

PCB Design

After completing the circuit design, we will start the PCB design to convert the circuit diagram into the actual PCB layout to ensure the correctness, reliability and performance of the circuit.

Production documents

Finally, we generate the necessary files for the manufacturing of the product, e.g. Gerber file, 2D CAD, BOM list for mass production

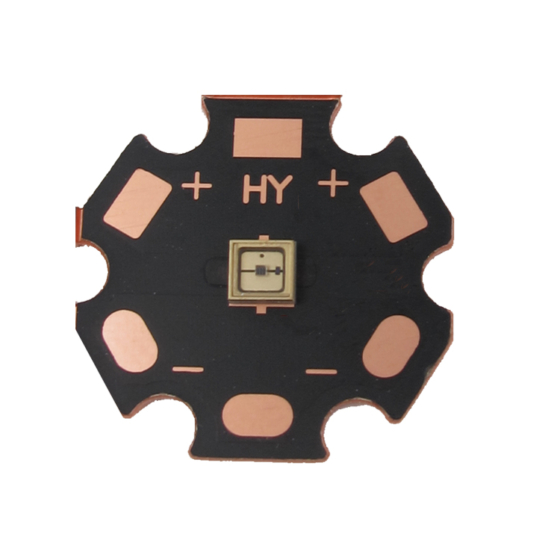

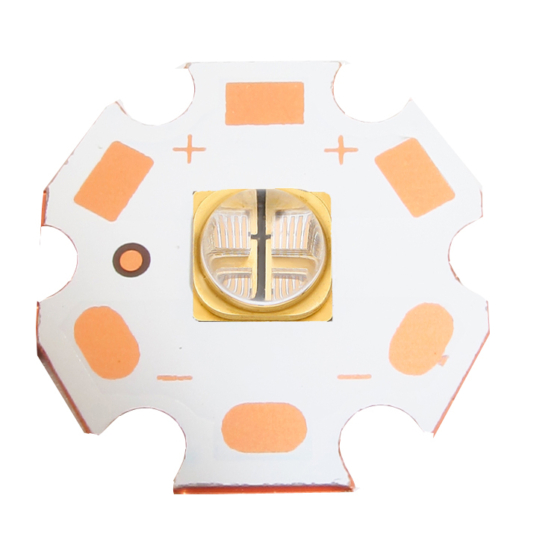

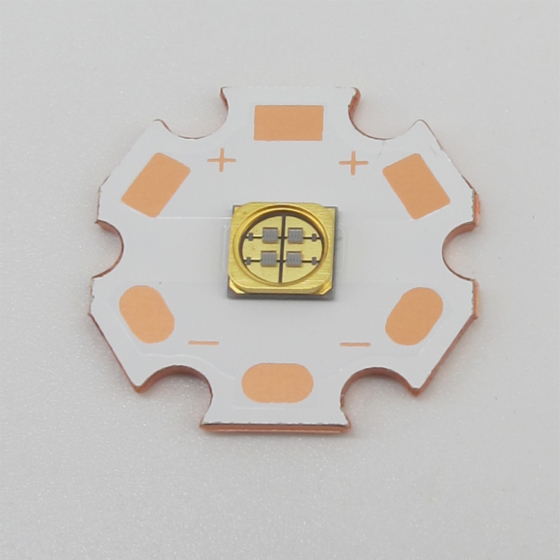

SMD Packages

| Product model | Voltage

(V) |

Peak Wavelengthl

(nm) |

Optical Power

(mW) |

RdiantIntensity uw/cm²(1cm) | Current

(mA) |

Spectrum Half width(nm) |

Angle |

| HYE35P20F250AG-P1 | 5.5-6.0 | 250-260 | 25-30 | 2718 | 150 | 11 | 120 |

| HYE35P20D250AG-P1 | 5.5-6.0 | 250-260 | 30-35 | 2278 | 150 | 11 | 120 |

| HYE35P20F260AG-P1 | 5.0-5.5 | 260-270 | 30-35 | 3244 | 150 | 11 | 120 |

| HYE35P20F270AG-P1 | 5.0-5.5 | 270-280 | 30-35 | 4560 | 150 | 11 | 120 |

| HYE35P22D270AG-P1 | 5.0-5.5 | 270-280 | 80-90 | 6144 | 250 | 11 | 120 |

| HYE35P30F250AG-P1 | 5.5-6.0 | 250-260 | 50-60 | 5571 | 350 | 11 | 120 |

| HYE35P30F260AG-P1 | 5.0-5.5 | 260-270 | 50-60 | 5546 | 350 | 11 | 120 |

| HYE35P30F270AG-P1 | 5.0-5.5 | 270-280 | 50-60 | 5571 | 350 | 11 | 120 |

| HYF38P20F250AG-X1 | 5.5-6.0 | 250-260 | 25-30 | 9177 | 150 | 11 | 60 |

| HYF38P20D250AG-X1 | 5.5-6.0 | 250-260 | 30-35 | 8727 | 150 | 11 | 60 |

| HYF38P20F260AG-X1 | 5.0-5.5 | 260-270 | 30-35 | 10301 | 150 | 11 | 60 |

| HYF38P20F270AG-X1 | 5.0-5.5 | 270-280 | 30-35 | 11814 | 150 | 11 | 60 |

| HYF38P22F270AG-X1 | 5.0-5.5 | 270-280 | 80-90 | 23550 | 250 | 11 | 60 |

| HYF38P30F250AG-X1 | 5.5-6.0 | 250-260 | 50-60 | 26744 | 350 | 11 | 60 |

| HYF38P30F260AG-X1 | 5.0-5.5 | 260-270 | 50-60 | 28038 | 350 | 11 | 60 |

| HYF38P20F250AG-S1 | 5.5-6.0 | 250-260 | 25-30 | 10515 | 150 | 11 | 30 |

| HYF38P20D250AG-S1 | 5.5-6.0 | 250-260 | 30-35 | 15972 | 150 | 11 | 30 |

| HYF38P20F260AG-S1 | 5.0-5.5 | 260-270 | 30-35 | 11874 | 150 | 11 | 30 |

| HYF38P20F270AG-S1 | 5.0-5.5 | 270-280 | 30-35 | 21872 | 150 | 11 | 30 |

| HYF38P22D270AG-S1 | 5.0-5.5 | 270-280 | 80-90 | 43160 | 250 | 11 | 30 |

| HYF38P30F250AG-S1 | 5.5-6.0 | 250-260 | 50-60 | 35123 | 350 | 11 | 30 |

| HYF38P30F260AG-S1 | 5.0-5.5 | 260-270 | 50-60 | 35007 | 350 | 11 | 30 |

| HYF38P30F270AG-S1 | 5.0-5.5 | 270-280 | 50-60 | 35407 | 350 | 11 | 30 |

Warmth Hint: The company is willing to personalize your customized products.

The greater the irradiation dose, the higher the disinfection efficiency.

The higher the UVC light power, the shorter the time required to kill bacteria and viruses, and vice versa, the lower the light power,The longer it takes to sterilize.

Solar simulator LED module 200-1750nm

Solar simulator LED module 200-1750nm