UV-C LED Technology

UVC-based disinfection, often called, Ultraviolet germicidal irradiation (UVGI), is the use of ultraviolet (ultravioleta) light to kill or inactivate viral, bacterial, and fungal species. When UV-C light is incident upon the target, the incident photons are absorbed by DNA or RNA, causing inactivation of the DNA or RNA double helix strands through the formation of molecular lesions. When enough of these lesions are created, the replication process is disrupted, and the cell cannot replicate. Absorption by proteins can lead to the breakdown of the organism’s cell walls causing the cell to die. For most commercial applications, replication prevention is sufficient. The UV doses required to prevent replication are much lower than required to kill, making the cost of UV treatment to prevent infection commercially viable

UVC LED Disinfection

UV-C based LEDs are a relatively new technology. Examples of wavelengths currently commercially available include 255nm, 265Nuevo Méjico, 275Nuevo Méjico, and 222nm. Sin embargo, UV-C LED technology se está desarrollando rápidamente, y con el tiempo se desarrollarán nuevas longitudes de onda, Los costos se reducirán y las eficiencias aumentarán, como ya ha sucedido dentro de la zona roja., infrarrojo, azul, y rangos de LED de longitud de onda UV-A.

A wavelength of 265nm is considered the optimum as it’s the peak of the DNA absorption curve. Sin embargo, disinfection and sterilization occur over a range of wavelengths. UV-C LEDs can be manufactured to target very specific and narrow wavelengths. This allows solutions to be tailored to the particular application need.

LED UVC frente a. Tecnologías tradicionales

Many applications use Mercury based UV lamps for UV disinfection applications but this technology has a number of disadvantages versus LED technology. Existe una mayor regulación sobre el uso del mercurio y su impacto ambiental, lo que resulta en mayores costos de eliminación y prohibiciones propuestas en algunos países.. Estos sistemas también requieren el uso de cloro para permitir la desinfección y, por lo general, son mucho más grandes que los sistemas basados en LED..

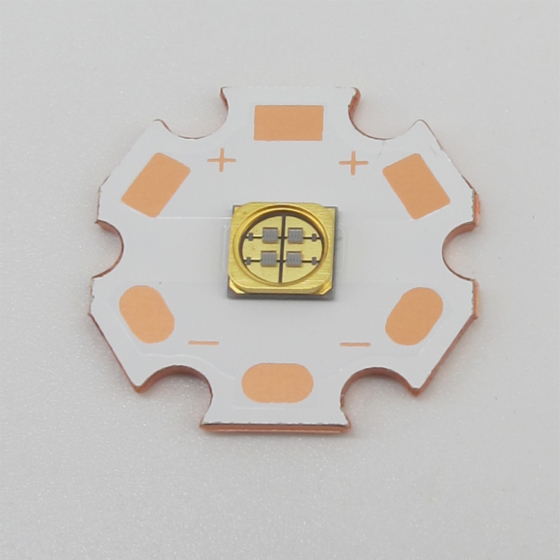

UVC LED Modules Application:

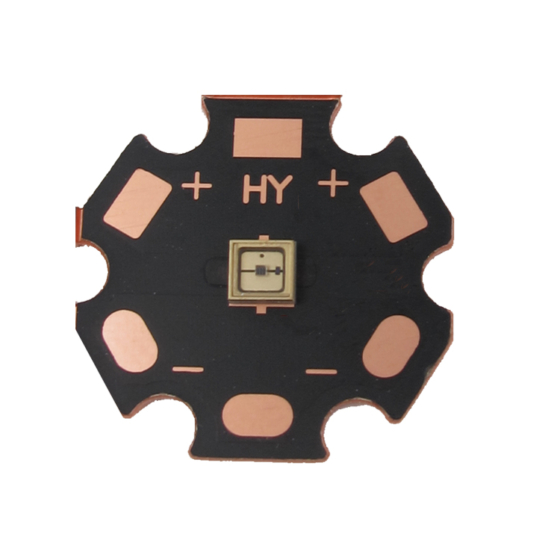

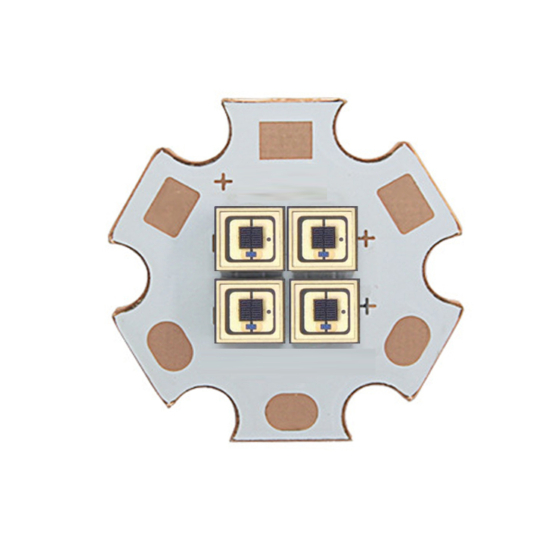

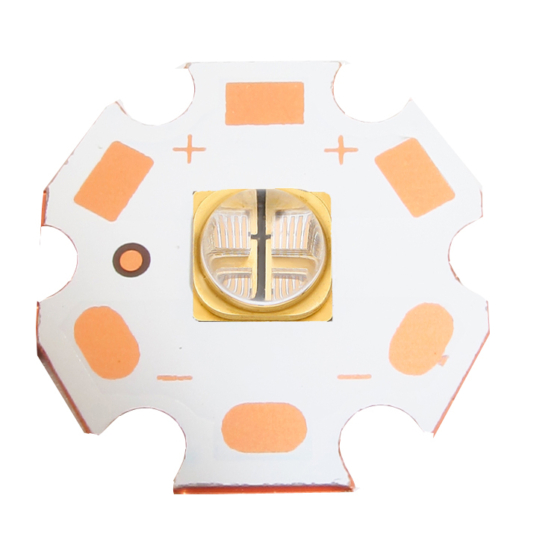

| Product model |

Voltaje (V) |

Peak Wavelengthl (Nuevo Méjico) |

Potencia óptica (mW) |

RdiantIntensity uw/cm²(1centímetro) |

Current (mamá) |

Mitad del espectro (Nuevo Méjico) |

Ángulo |

| HYE35P20F250AG-P1 | 5.5-6.0 | 250-260 | 25-30 | 2718 | 150 | 11 | 120 |

| HYE35P20D250AG-P1 | 5.5-6.0 | 250-260 | 30-35 | 2278 | 150 | 11 | 120 |

| HYE35P20F260AG-P1 | 5.0-5.5 | 260-270 | 30-35 | 3244 | 150 | 11 | 120 |

| HYE35P20F270AG-P1 | 5.0-5.5 | 270-280 | 30-35 | 4560 | 150 | 11 | 120 |

| HYE35P22D270AG-P1 | 5.0-5.5 | 270-280 | 80-90 | 6144 | 250 | 11 | 120 |

| HYE35P30F250AG-P1 | 5.5-6.0 | 250-260 | 50-60 | 5571 | 350 | 11 | 120 |

| HYE35P30F260AG-P1 | 5.0-5.5 | 260-270 | 50-60 | 5546 | 350 | 11 | 120 |

| HYE35P30F270AG-P1 | 5.0-5.5 | 270-280 | 50-60 | 5571 | 350 | 11 | 120 |

| HYF38P20F250AG-D1 | 5.5-6.0 | 250-260 | 25-30 | 9177 | 150 | 11 | 120 |

| HYF38P20D250AG-D1 | 5.5-6.0 | 250-260 | 30-35 | 8727 | 150 | 11 | 120 |

| HYF38P20F260AG-D1 | 5.0-5.5 | 260-270 | 30-35 | 10301 | 150 | 11 | 120 |

| HYF38P20F270AG-D1 | 5.0-5.5 | 270-280 | 30-35 | 11814 | 150 | 11 | 120 |

| HYF38P22F270AG-D1 | 5.0-5.5 | 270-280 | 80-90 | 23550 | 250 | 11 | 120 |

| HYF38P30F250AG-D1 | 5.5-6.0 | 250-260 | 50-60 | 26744 | 350 | 11 | 120 |

| HYF38P30F260AG-D1 | 5.0-5.5 | 260-270 | 50-60 | 28038 | 350 | 11 | 120 |

| HYF38P20F250AG-S1 | 5.5-6.0 | 250-260 | 25-30 | 10515 | 150 | 11 | 30 |

| HYF38P20D250AG-S1 | 5.5-6.0 | 250-260 | 30-35 | 15972 | 150 | 11 | 30 |

| HYF38P20F260AG-S1 | 5.0-5.5 | 260-270 | 30-35 | 11874 | 150 | 11 | 30 |

| HYF38P20F270AG-S1 | 5.0-5.5 | 270-280 | 30-35 | 21872 | 150 | 11 | 30 |

| HYF38P22D270AG-S1 | 5.0-5.5 | 270-280 | 80-90 | 43160 | 250 | 11 | 30 |

| HYF38P30F250AG-S1 | 5.5-6.0 | 250-260 | 50-60 | 35123 | 350 | 11 | 30 |

| HYF38P30F260AG-S1 | 5.0-5.5 | 260-270 | 50-60 | 35007 | 350 | 11 | 30 |

| HYF38P30F270AG-S1 | 5.0-5.5 | 270-280 | 50-60 | 35407 | 350 | 11 | 30 |

Consejo de calidez: The company is willing to personalize your customized products.

The greater the irradiation dose, the higher the disinfection efficiency.

The higher the UVB light power, the shorter the time required to kill bacteria and viruses, and vice versa, the lower the light power,The longer it takes to sterilize.

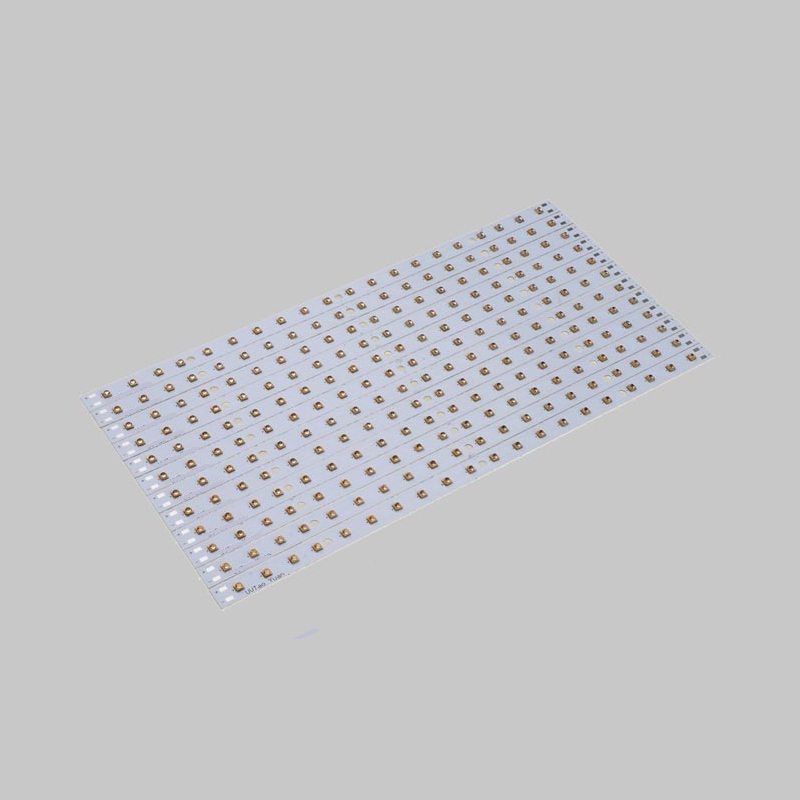

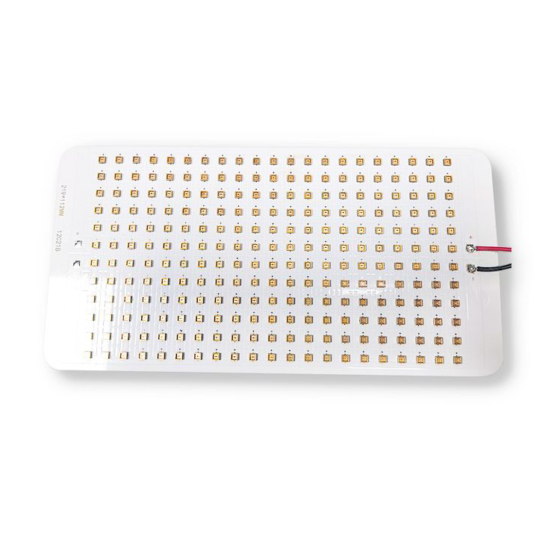

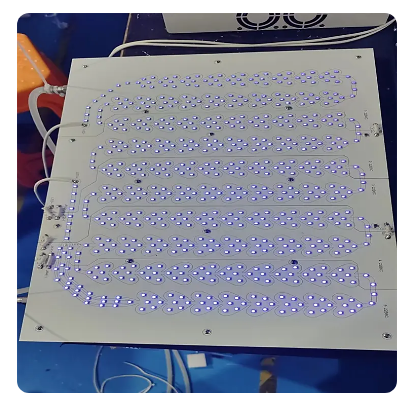

Módulo de placa PCBA de simulador solar LED 200-1750 nm

Módulo de placa PCBA de simulador solar LED 200-1750 nm