El diseño del sistema óptico del simulador solar LED debe pasar por el procesamiento de “sistema de fuente de luz – condensador – integrador óptico – espejo colimador”. A través de la colaboración de múltiples componentes, simula la irradiación solar y equilibra la colimación, uniformity and spectral matching. The light source system uses a specific collimating lens to reduce the divergence angle to within 2° and matches the spectrum according to AM1.5. The condenser uses a parabolic mirror to reduce loss, the optical integrator uses reflection to even out the light, and the collimating mirror emits a parallel light spot. Relying on the group’s nearly 20 years of experience in high-end testing equipment research and development, Zicuang Measurement and Control’s Luminbox has achieved coverage of three technical routes: LED, halogen lamps, and xenon lamps. The following text will detail the optical system design of the LED solar simulator.

The Composition and Working Principle of LED Solar Simulator

1_upscayl_3x_high-fidelity-4x.png

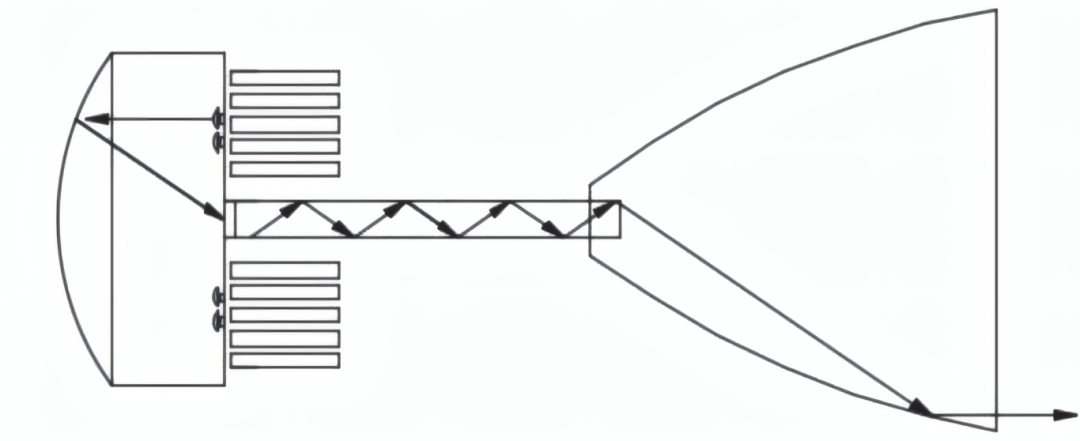

Optical structure schematic diagram of LED solar simulator

The LED solar simulator is mainly composed of LED light source, small-angle collimating lens, parabolic mirror, optical integrator and so on. When the LED solar simulator is working, the Lambertian light emitted by the LED light source is transformed into a parallel light beam after passing through the collimating lens. This light beam is converged by the parabolic mirror and enters the optical integrator, where multiple reflections occur. Each reflection forms a virtual light source, and the uniform light is ultimately achieved through the superposition of multiple virtual light sources. The uniform light beam then exits in parallel through the parabolic mirror and forms a uniform irradiation surface on the test surface at a certain distance. When viewed from the direction of the incident light, it appears as if it is coming from the “infinite distance” of the sun, thereby simulating the solar irradiation.

Light source system design

Collimated light design

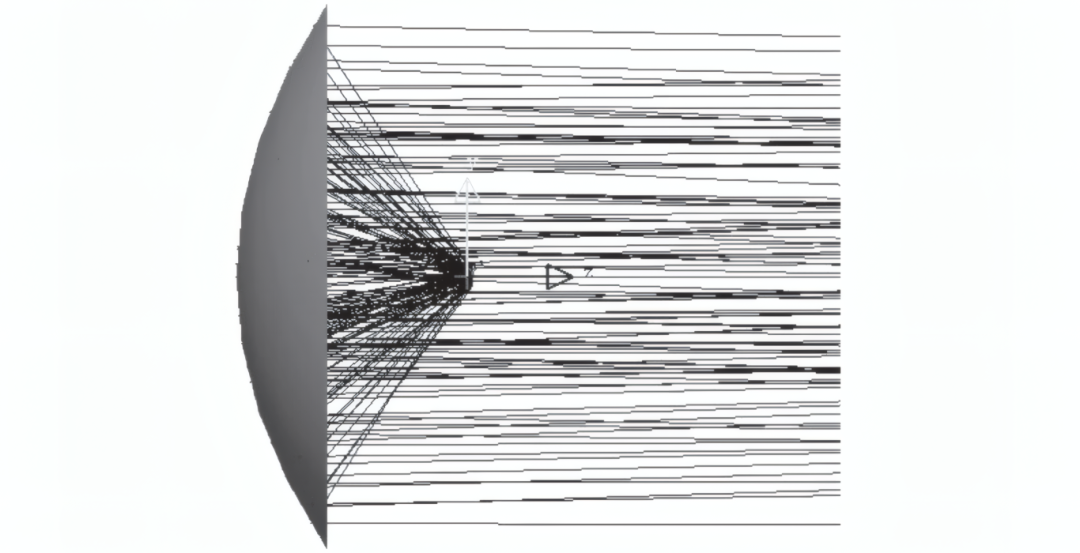

Collimated post-distribution curve of 2_upscayl_3x_high-fidelity-4x.png

The light emitted by the LED follows a Lambertian distribution and has a large divergence angle (the half-angle is usually greater than 60°), thus requiring secondary optical distribution to achieve collimation of the light path. In the design, a small-angle collimating lens based on the theory of surface light sources and marginal rays is adopted. The lens material is made of polymethyl methacrylate with a refractive index of 1.49, which has high light transmittance and low processing cost. Through the refraction regulation of the light by the lens, the divergence angle (half-angle) of the light can be reduced to within 2°. This design ensures that the light is concentratedly incident within the aperture of the optical integrator, significantly improving the utilization rate of light energy and laying a foundation for subsequent uniform light distribution and collimation.

2. Spectral Design

Spectral matching is the core indicator for simulating natural light. LED chip selection and combination should be based on the AM1.5 standard solar spectrum. The design covers the spectral range of 300nm to 1100nm, and single-band LED chips are selected in eight key bands (300-400Nuevo Méjico, 400-500Nuevo Méjico, 500-600Nuevo Méjico, 600-700Nuevo Méjico, 700-800Nuevo Méjico, 800-900Nuevo Méjico, 900-1000Nuevo Méjico, 1000-1100Nuevo Méjico) and arranged in an array on the substrate. By precisely controlling the driving current and light intensity output of each band’s LED chips, a high similarity match with the AM1.5 spectrum can be achieved, meeting the spectral requirements of different application scenarios.

Condenser lens design

3_upscayl_3x_high-fidelity-4x.png

Parabolic mirror concentration simulation

The condenser adopts a parabolic mirror, whose optical characteristics are as follows: light rays parallel to the symmetry axis, after reflection, can all converge at a single focus without geometric aberration, and it also satisfies the reversibility of the optical path (light rays emitted from the focus can form parallel light after reflection). The design parameters need to be matched with the collimating lens array to ensure that the parallel light output by the collimating lens can be efficiently converged to the focus position, and the focus position precisely corresponds to the input port of the subsequent light homogenizing component, minimizing light energy loss.

Optical Integrator Design

As a core uniform light component, the optical integrator converts the non-uniform light after convergence into a uniform beam through multiple total reflections on its inner walls. The principle of its uniform light is that when the incident light is reflected on the inner wall of the light-mixing rod, multiple “virtual light sources” are formed, and the uniformity of the emitted light is ultimately achieved through the superposition of multiple virtual light sources. In the design, three parameters need to be considered: first, the cross-sectional shape, a square or regular hexagonal cross-section can achieve higher illumination uniformity; second, the length, too long will lead to increased light energy loss, and too short will result in insufficient uniform light; third, the spatial and angular distribution of the incident light.

The design of collimating reflector

Although the light after being homogenized by the optical integrator has excellent uniformity, it needs to pass through a collimating mirror to achieve parallel output of a large-sized light spot. Although the imaging system of the solar simulator is not aimed at improving the imaging quality, large aberrations will reduce the light energy utilization rate of the irradiation surface of the solar simulation system. Therefore, in the design, a parabolic mirror can be used for collimation. The top of the parabolic mirror is opened, and the output port of the optical integrator is placed at the focus of the parabolic mirror.

In summary, the optical system design of the LED solar simulator is an engineering project that requires precise coordination among all core components: The light source system reduces the divergence angle through a collimating lens, and multi-band chips match the AM1.5 spectrum. The condenser lens connects the focus to reduce light energy loss. The optical integrator ensures uniform light distribution with reasonable parameters. The collimating reflector ultimately achieves the output of a large-sized parallel light spot. Each link closely adheres to the goal of “efficient light transmission and precise simulation”, providing equipment support for experimental research and technological innovation in related fields.

Heyi Large Area LED Solar Simulator PCB module

The Heyi full-spectrum large-area LED solar simulator from Heyi Measurement and Control achieves a triple breakthrough in uniform irradiation, precise spectrum and stable operation with A+AA+ comprehensive performance. It has passed authoritative certification and provides a highly reliable and standardized full-spectrum lighting solution for material testing, promoting the advancement of photocatalytic activity testing towards higher precision and repeatability.

Módulo de placa PCBA de simulador solar LED 200-1750 nm

Módulo de placa PCBA de simulador solar LED 200-1750 nm