Photocatalytic materials serve as the core material for achieving efficient conversion and utilization of solar energy. The performance testing of these materials directly determines the industrialization potential of related technologies. Precise assessment of material performance cannot be achieved without the stable reproduction of solar spectra and irradiation conditions. Solar simulators are an important tool in this process. Leveraging professional expertise and technological accumulation, we can provide a full-chain support for the testing of photocatalytic materials, ranging from laboratory research to industrial verification. This article will systematically elaborate on the key applications of solar simulators in the testing of photocatalytic materials. Evaluation of photocatalytic activity using solar light simulator

Solar light simulator assists in hydrogen production from photocatalytic materials

The solar light simulator provides standardized lighting conditions for the activity test of photocatalytic materials. For example, in the research of water splitting for hydrogen production, the simulator can precisely control the AM1.5G standard spectrum (1000W/m²) to test the hydrogen production efficiency of photocatalysts. In addition, the simulator can adjust the light intensity and wavelength to study the activity differences of the materials under different lighting conditions, such as by adjusting the incident angle of the light beam and the spectral composition, to simulate the sunlight at different latitudes and times, and study the photochemical reaction kinetics on the material surface.

Solar light simulators assist in screening high-performance materials

The core objective of developing photocatalytic materials is to enhance energy conversion efficiency. The flexible control capabilities of solar light simulators provide an efficient testing method for material optimization. By changing the light parameters, high-performance materials suitable for specific scenarios can be quickly selected. In the research of visible light-responsive materials, a full-spectrum LED solar simulator can adjust the spectrum in segments and test the material’s utilization efficiency in the 400-760nm wavelength band separately. For example, when screening bismuth-based composite photocatalysts, the oxygen production rate at blue and green light wavelengths can be tested separately to clearly identify the spectral response advantage range of the material and provide a direction for element doping optimization.

Solar light simulators test the stability and durability of materials

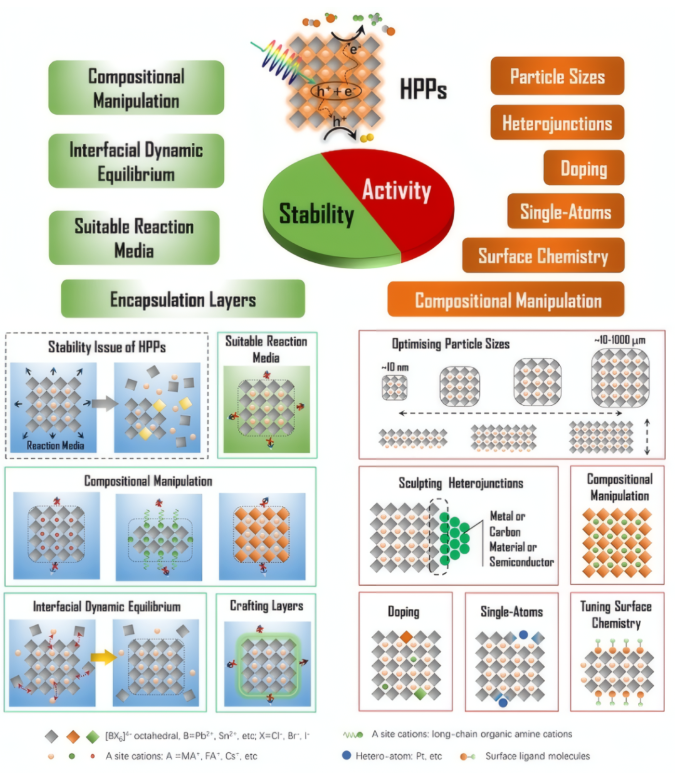

Strategies for Improving the Stability and Catalytic Activity of Perovskite Photocatalytic Materials

The long-term stability of photocatalytic materials is crucial for practical applications. A solar simulator can simulate the durability of materials in natural environments through continuous illumination for a long period (such as several hundred hours). For example, in the testing of perovskite photocatalysts, the stable irradiance of the simulator (1000W/m² ± 2%) can assess the activity decay of the material after multiple cycles.

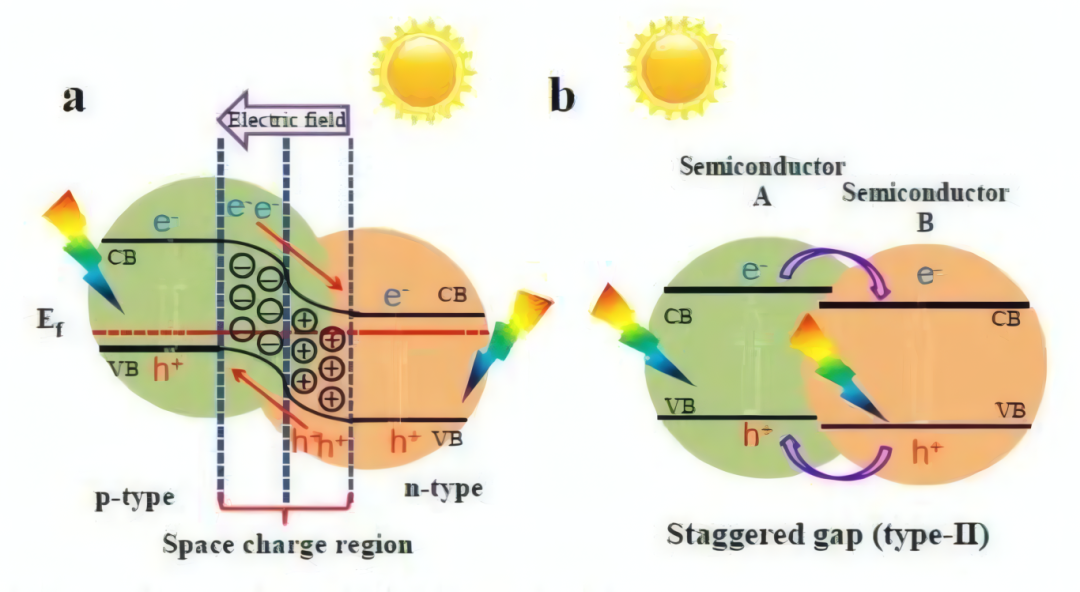

The solar simulator reveals the laws of photocatalytic reactions

The microscopic mechanism research of photocatalytic reactions requires precise control of the interaction process between light and the material. The solar simulator combined with in-situ characterization techniques can track the dynamic processes of charge separation, migration, and surface reactions, providing theoretical basis for material design. For example, in the study of the Sb2S3@CdSexS1-x heterojunction photocatalytic anode, using the pulsed light source of the solar simulator and in-situ characterization techniques, the promoting effect of the S-type heterojunction on the separation of photogenerated carriers was revealed. In addition, the simulator can be combined with spectrometers, mass spectrometers, etc., to monitor reaction intermediates in real time and analyze the detailed mechanisms of processes such as CO2 reduction and degradation of organic pollutants.

Research and application of multi-scenario connection experiments simulated by the solar simulator

A natural photosynthesis, B schematic diagram of artificial photosynthesis (photo-catalytic CO2 reduction reaction)

The solar light simulator can simulate various actual lighting environments and supports the performance evaluation of materials in different application scenarios. For example, in CO2 reduction research, the simulator can simultaneously control the spectrum (such as AM1.5G) and the gas atmosphere (such as CO2 concentration), testing the catalytic performance of materials under simulated industrial exhaust conditions. Research shows that the In-doped Bi2O3-modified oxidized foam copper photoanode, under the solar light simulator, has a Faradaic efficiency of HCOOH of up to 97.8%, and has excellent stability. In addition, the dynamic adjustment function of the solar light simulator (such as the gradual change program of light intensity) can simulate the natural light cycle and evaluate the adaptability of photocatalytic materials in the real environment.

As the core tool for testing photocatalytic materials, the precise simulation ability and flexible regulation feature of the solar light simulator have promoted the rapid development of the photocatalysis field. With the continuous advancement of technology, the solar light simulator has continuously broken through in aspects such as spectral matching, stability, and intelligence, providing a solid foundation for the development and application of efficient photocatalytic materials. In the future, with the integration of multiple disciplines, the HEYI solar light simulator LED module will further improve the test accuracy and efficiency, helping to promote the large-scale application of photocatalytic technology in energy and environment fields.

LED Solar simulator PCBA board module 200-1750nm

LED Solar simulator PCBA board module 200-1750nm